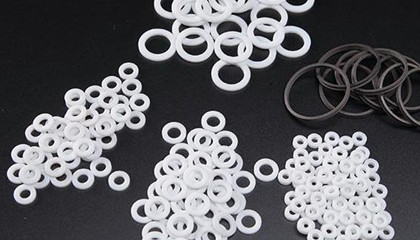

氣動(dòng)液壓元件 2

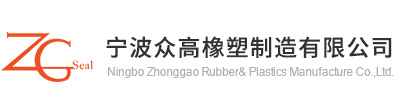

APP&AGP尺寸表

| 裝配/溝槽尺寸 | |||||

|

D |

d |

H |

D1 |

G |

L |

|

6 |

3 |

2.2 |

5.5 |

2.6 |

2.5 |

|

8 |

4 |

2.9 |

7.5 |

3.3 |

2.5 |

|

10 |

6 |

2.9 |

9.5 |

3.3 |

2.5 |

|

12 |

8 |

2.9 |

11.5 |

3.3 |

2.5 |

|

15 |

10 |

3.6 |

14 |

4 |

2.5 |

|

16 |

11 |

3.6 |

15 |

4 |

2.5 |

|

20 |

14 |

4.3 |

19 |

4.7 |

3 |

|

25 |

17 |

5.3 |

24 |

5.7 |

3 |

|

32 |

24 |

5.3 |

31 |

5.7 |

3 |

|

40 |

30 |

6.5 |

39 |

7 |

3 |

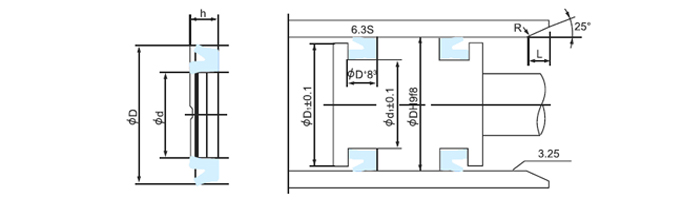

PPY尺寸表

| 產(chǎn)品編號(hào) |

裝配/溝槽尺寸 |

|||||

|

D |

d |

H |

G |

D1 |

L |

|

|

PPY-6 |

6 |

3 |

2.2 |

5.5 |

2.6 |

2.5 |

|

-8 |

8 |

3 |

2.2 |

7.5 |

3.3 |

2.5 |

|

-10 |

10 |

6 |

2.9 |

7.5 |

3.3 |

2.5 |

|

-12 |

12 |

8 |

2.9 |

11.5 |

3.3 |

2.5 |

|

-15 |

15 |

10 |

3.6 |

14 |

4 |

2.5 |

|

-16 |

16 |

11 |

3.6 |

15 |

4 |

2.5 |

|

-20 |

20 |

14 |

4.3 |

19 |

4.7 |

3 |

|

-25 |

25 |

17 |

5.3 |

24 |

5.7 |

3 |

|

-32 |

32 |

40 |

5.3 |

31 |

5.7 |

3 |

|

-40 |

40 |

30 |

6.5 |

39 |

7 |

3 |

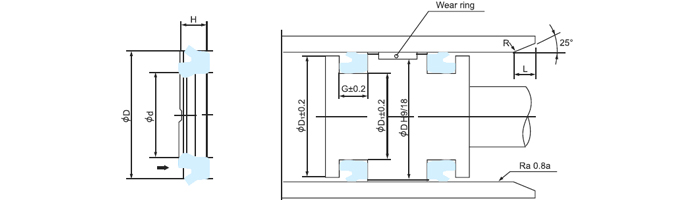

PDU尺寸表

| 產(chǎn)品編號(hào) |

裝配/溝槽尺寸 |

||||||||

|

d |

D |

H |

T |

G |

C |

B |

R |

I |

|

|

PDU-8 |

8 |

12 |

4.7 |

3.5 |

4 |

9.6 |

2 |

0.5 |

1.5 |

|

-10 |

10 |

14 |

4.7 |

3.5 |

4 |

11.6 |

2 |

0.5 |

1.5 |

|

-12 |

12 |

16 |

4.7 |

3.5 |

4 |

13.6 |

2 |

0.5 |

1.5 |

|

-14 |

14 |

18 |

4.7 |

3.5 |

4 |

15.6 |

2 |

0.5 |

1.5 |

|

-16 |

16 |

24 |

7.3 |

5.5 |

6 |

19.4 |

2 |

0.6 |

2 |

|

-20 |

20 |

28 |

7.3 |

5.5 |

6 |

23.4 |

2 |

0.6 |

2 |

|

-25 |

25 |

33 |

7.3 |

5.5 |

6 |

28.4 |

2 |

0.6 |

2 |

|

-30 |

30 |

470 |

8.5 |

6.5 |

7 |

34.0 |

2 |

0.8 |

2.5 |

|

-32 |

32 |

40 |

8.5 |

6.5 |

7 |

36.0 |

2 |

0.8 |

2.5 |

|

-35 |

35 |

45 |

8.5 |

6.5 |

7 |

39.0 |

2 |

0.8 |

2.5 |

|

-40 |

40 |

50 |

805 |

6.5 |

7 |

44.0 |

2 |

0.8 |

2.5 |

|

-45 |

45 |

55 |

8.5 |

6.5 |

7 |

49.0 |

2 |

0.8 |

2.5 |

相關(guān)資訊

骨架油封失效原因分析(一) 2014-03-24

骨架油封失效原因分析(一) 2014-03-24 骨架油封制造時(shí)需控制好哪些質(zhì)量要點(diǎn)? 2023-01-04

骨架油封制造時(shí)需控制好哪些質(zhì)量要點(diǎn)? 2023-01-04 導(dǎo)致O型圈失效的常見原因和預(yù)防方式 2023-06-25

導(dǎo)致O型圈失效的常見原因和預(yù)防方式 2023-06-25 初步生產(chǎn) 2012-10-09

初步生產(chǎn) 2012-10-09 平墊圈的改進(jìn)磨削法 2013-05-07

平墊圈的改進(jìn)磨削法 2013-05-07 動(dòng)密封用O型圈壓縮量應(yīng)小于靜密封O型圈壓縮量 2012-06-28

動(dòng)密封用O型圈壓縮量應(yīng)小于靜密封O型圈壓縮量 2012-06-28 橡膠涂層O型圈的耐油性 2022-07-06

橡膠涂層O型圈的耐油性 2022-07-06 O型密封圈失效的這幾個(gè)原因需掌握 2024-03-29

O型密封圈失效的這幾個(gè)原因需掌握 2024-03-29 發(fā)泡橡膠條的特點(diǎn)和用途 2022-12-26

發(fā)泡橡膠條的特點(diǎn)和用途 2022-12-26 格萊圈斯特封的采購(gòu)和安裝注意事項(xiàng) 2023-03-09

格萊圈斯特封的采購(gòu)和安裝注意事項(xiàng) 2023-03-09

下一篇:氣動(dòng)液壓元件 3

返回